The revolutionary Honda 750 Four. The roots of its engine architecture go all the way back to Italy.

2019 celebrated the 50th anniversary of the launch of the Honda CB750, a ground-breaking motorcycle design that became the basic blueprint for other Japanese manufacturers to emulate. It was a breakthrough in its engine architecture – an across the frame single overhead camshaft four-cylinder four-stroke at a price that motorcyclists of the day could afford. When Kawasaki, Suzuki and Yamaha released their spin on the same fundamental concept, motorcyclists had a range of machinery to choose from that provided outstanding performance, reliability, handling and finish. During the 1970s, these machines were often referred to, perhaps somewhat unfairly, as UJMs, or the Universal Japanese Motorcycle. This same engine layout still dominates the model line-ups of the Japanese and many European manufacturers to this day.

However, it was a design by Italian engineers Carlo Gianini and Piero Remor for a competition racing engine that cast the die for this configuration. After graduating from Rome University in 1923, the two engineers were resolute about producing a single overhead camshaft (SOHC) four-cylinder engine that, uniquely, would sit transversely across the frame for better cooling of the cylinders.

Although Belgium company F.N. and American motorcycle manufacturer Henderson had already built four-cylinder motorcycles in 1905 and 1912, the designs placed the engine longitudinally in the frame. This configuration tended to overheat the rear two cylinders as not enough cooling air could reach them.

After acquiring a small workshop in Rome, the two young engineers came to the attention of a wealthy industrialist Count Bonmartini. In 1924 the Count formed a company called GRB using the initials of the trio’s surname. The prototype was a SOHC design, governed by bevel gears via a shaft in front of the vertical cylinders. It boasted a bore and stroke of 51 x 60mm for a capacity of 490cc and produced approximately 26 to 28bhp at 6000rpm. Nevertheless, the project was shelved for several years but was resurrected in 1927 when Count Bonmartini and kindred spirit Count Lancelloti injected capital into a new engineering firm called Officina Precisione Romana Automobili, or OPRA.

The larger premises were equipped with precision tooling, and Gianini and Remor developed several different designs. By 1928 the engine was ready to be fitted into a chassis, and a rider was sought. Piero Taruffi was a prominent racer In Italian national events on his 500cc Norton and had recently finished his engineering studies. He was a natural choice to become OPRA’s development rider.

The prototype had evolved into a mixture of air and water-cooling with the four cylinders cast as a single block with individual heads that sported double overhead camshafts. It utilised two valves per cylinder set at 90 degrees in a hemispherical combustion chamber. Engine power was believed to be 32 to 34 bhp at 7000rpm, which was exceptional for the era. Bonmartini

entered the machine in Rome’s Royal GP with former Italian National Champion Umberto Faraglia as the rider. Faraglia led the race for three laps, but ironically Taruffi took the lead, and the OPRA blew up chasing the Norton.

Taruffi went on to win the 1928 Italian National Championship on his Norton and finally got to race the OPRA in 1929 at the Belfiore circuit in Mantua. Piero led until the penultimate lap when the engine again blew up. The disappointment of the OPRA team saw the racer retired to one side of the workshop.

Count Bonmartini by now was putting his energies into a new aviation company he had formed, Compagnia Nazionale Aeronautica or CNA, utilising the talents of Giannini to design experimental aero engines. Remor, however, fell out of favour with Bonmartini and left the company. The Count was still very much a racer, though, resurrecting the OPRA project with Gianini, and draughtsman Luigi Fonzi was brought into the project.

Supercharging was now seen as the best solution to boosting horsepower, and in 1933 the CNA design sported this technology. It borrowed little from the OPRA design as the cylinders now had a bore and stroke of 52 x 58mm and were canted forward by 45 degrees to allow a supercharger to sit above the crankcases. The cylinders were water-cooled while the cylinder heads utilised double overhead camshafts (DOHC) with two valves per cylinder again set at 90 degrees. Taruffi influenced much of the design and was considered responsible for using a car like supercharger.

By early 1934 the machine was ready for testing and was named Rondine (Swallow) by the Count. Taruffi was not available to test the Rondine due to a racing car accident, and a rider named Amilcare Rossetti was enlisted to perform the shakedown runs.

The CNA Rondine debuted at the 1935 Tripoli GP, with riders Taruffi and Rossetti claiming 1st and 2nd. Both machines sported revolutionary “dolphin” fairings as Taruffi was well aware of the benefits of good aerodynamics, thanks to his car racing experience. The next race was the Coppa Acerbo in Pesaro, and although CNA entered a three-rider line-up, Taruffi took the Rondine to a win. The Italian G.P. followed but was a disappointment for the CNA team as all three riders had mechanical problems, with the only consolation a 5th place and a lap record of 107mph (172.2kph).

Taruffi did capture several world records for the 500cc class over the Kilometre and mile at 152mph (244.62kph), but the racing days of the Rondine were over. Count Bonmartini decided to retire and sold the company to the Caproni aeroplane organisation. Gianni Caproni had no interest in the Rondine, and he charged Taruffi with finding a buyer for the machines.

Not far from the Monza Circuit, motorcycle manufacturer Guiseppe Gilera based in Arcore received Taruffi with open arms. He insisted that Piero accompany the six Rondine machines and work for him. Gilera also knew from experience that publicity from success in racing sold motorcycles.

The first thing that Gilera wanted to address was the fragility of the design’s crankshaft. Taruffi and Gilera worked on a redesign together, solving the problem by adopting roller bearings in duralium cages. Taruffi refined the Roots-type supercharger, and a new frame replaced the sheet steel unit with a tubular steel design but retained the pressed steel front forks with a single spring and friction damping. At the rear, a triangulated swinging fork was used and controlled by springs carried in horizontal tubes at wheel spindle height that utilised large friction dampers.

It was 1937 when Giuseppe Gilera decided to test the water in international racing. Success did not occur immediately but finally came when their number one rider, Aldrighetti, won the Italian G.P. at Monza. Taruffi had by now decided to concentrate on automobile racing. However, in October 1937, he briefly became the holder of the absolute motorcycle land speed record of 170.37mph (271.18kph) on the A4 Autostrada with the supercharged 500cc Gilera racer. Although it only stood for over a month, until Ernst Jakob Henne on a 500cc supercharged BMW exceeded the mark in November, his record for the hour of 127mph (205kph) stood for many years.

By 1939 the blown Gilera 500 produced 92bhp at 8,000rpm, enough to put it on equal terms with the supercharged BMW flat twins while possessing superior handling. It was enough for Gilera to win the European Championship (the precursor to the World Championship) when Dorino Serafini triumphed at the Swedish, German and Irish GP. The racing department developed an air-cooled 250cc four the following year using the experience gained on the 500 but with the supercharger mounted in front of the crankcases. It never saw competition but became the basis for the post-war 500cc Gilera.

After the hostilities of WW2, in November 1946, the Fédération Internationale des Clubs Motocyclistes (predecessor of the Fédération Internationale Motocycliste) banned supercharging from international competition. Without forced induction, the power of the 500cc racer dropped to almost half, from over 90bhp to 45bhp with negligible weight saving. The decision was quickly made to develop a new machine based on the technical advances of the Ing. Piero Remor designed pre-war 250cc four-cylinder. Taruffi had brought Remor into the team prior to the war, although he was initially pre-occupied in the prototype department before embarking on the new 500cc four-cylinder.

But the water-cooled pre-war CNA inspired racer had one last hurrah. With a pair of Weber carburettors replacing the supercharger, Nello Pagani managed to win the 1946 Italian National Championship. Sporadic appearances in 1947 and 1948 brought little success and saw the curtain finally close on the pre-war Gilera racer.

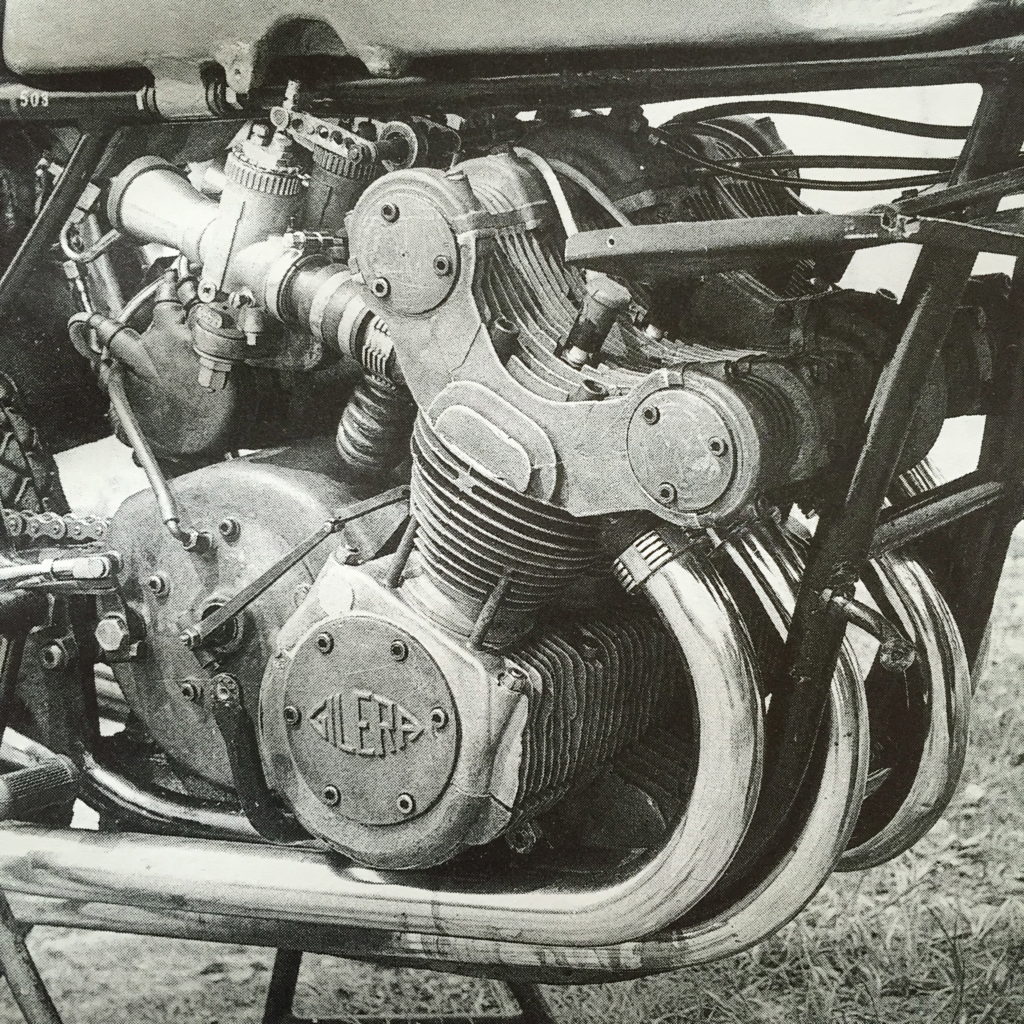

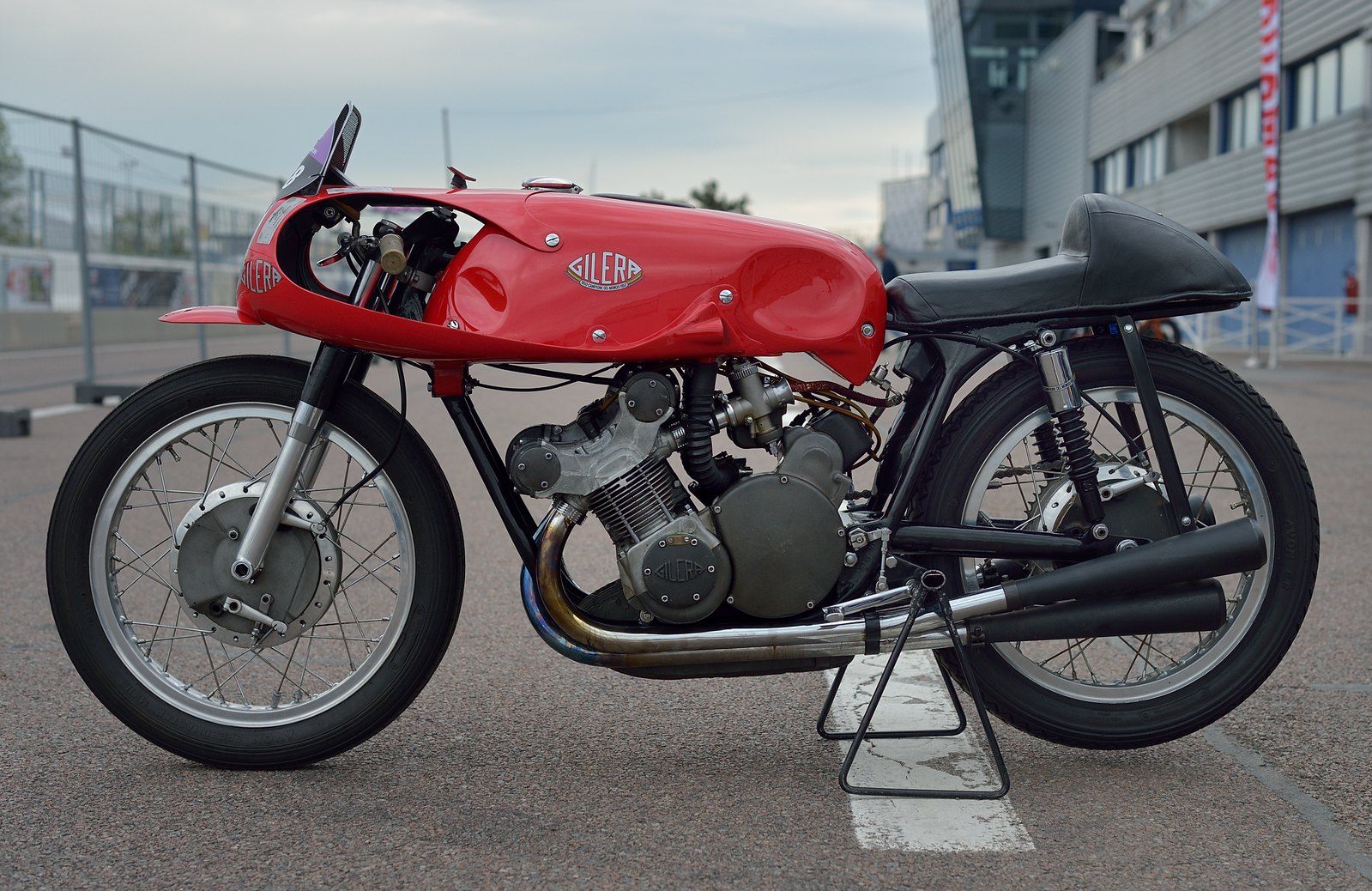

Ing. Remor’s new design was ready by the end of 1947. The air-cooled engine had its individual cylinders inclined at 30 degrees. It boasted double overhead camshafts with two valves per cylinder driven by gears running between the two pairs of cylinders. Lubrication was by wet sump incorporating the four-speed gearbox with a wet multi-plate clutch. Weber supplied a new model carburettor for each cylinder, and ignition problems were solved by using a Marelli magneto mounted vertically behind the cylinders. Primary drive was taken between the first and second cylinders, transmitting the 55hp at 8,500rpm produced to the rear wheel.

The engine was mounted in a steel tube frame which utilised a blade girder-type front forks with a central coil spring and torsion-bar swinging-arm rear suspension. What was impressive was the noticeable low weight of 125kg (275lb). And with the benefit of constant improvement, the design remained at the forefront of racing over the next decade.

But success was not to come immediately. At its race debut in May 1948 at Cesena, the experienced Nello Pagani could only describe the machine as “unrideable”. Much of 1948 was spent refining the Gilera by working on its high-speed handling and reliability due to its poor lubrication system. It didn’t stop Masserinni from winning the Italian G.P. on the Gilera, even though his teammate Bandirola blew up his machine without completing a lap.

1949 saw the newly named Fédération Internationale de Motocyclisme introduce the first 500cc World Championship series. The Gilera team riders consisted of Pagani, Bandirola and Arcisco Artesiani. The Championship was held over six rounds, with British rider Les Graham on the AJS E90 “Porcupine” twin beating Pagani and Gilera by a single point, which he gained from setting the fastest lap by a finishing competitor at Berne. Pagani had victories at Assen and Monza, taking second place in the Championship, while Artesiani claimed third place with consistent finishes in the top three at most rounds.

Ing. Remor suddenly left the Arcore factory at the end of the season, taking rider Artesiani and chief mechanic Arturo Magni with him. It’s fair to say that relationships between Remor, Guiseppe Gilera and some of the riders had become strained to breaking point. Remor also took the drawings of the next phase of the Gilera’s development to rival manufacturer M.V. Agusta. The 1950 M.V. Agusta racer was unveiled during the offseason and was seen by many as a clone of the Gilera four.

After Remor’s exit, Guiseppe Gilera re-hired Piero Taruffi as team manager and engaged Remor’s former assistants Franco Passoni and Alessandro Colombo as combined technical department heads. The main changes made to the racer was the adoption of paired cylinder heads, larger 30mm carburettors, full hub width front brakes and a return to the pre-war rear suspension system of horizontal cylindrical spring boxes beneath the saddle and friction damping. The engine’s lubrication system was also improved, and the power unit was now making 52bhp at 9000rpm.

For the 1950 season, Umberto Masetti was brought in to replace Artesiani in the Gilera rider line-up alongside Pangani and Bandirola. As only four of the highest points scoring places counted towards the six-round World Championship, Gilera opted to miss the opening round at the Isle of Man. They returned for the Belgian round at Spa, which was also the scene of the MV Agusta’s debut in the hands of Artesiani. Geoff Duke riding for Norton led initially until tyre troubles forced his retirement, giving Masetti the win with Pagani second and Bandirola in fourth for Gilera.

The Gilera team repeated the same finishing places at the following Dutch T.T. in Assen. In poor conditions at the Swiss GP in Geneva, Masetti managed a second-place, although he could only achieve sixth at the Ulster T.T. on the Clady circuit behind winner Geoff Duke. Duke won again in the final round at Monza, but Masetti managed second place to claim the title by a point for the Acore factory.

Pasoni redesigned the Gilera’s running gear during the off-season, taking a page out of Norton’s book by utilising a tube duplex frame with swinging fork rear suspension and hydraulic telescopic forks of the Norton type. Also, smaller diameter 19inch (48.26cm) wheels were adopted with a wider rim.

Despite this, Duke went on to win both the 1951 500cc and 350cc World Championship, the first double title in a single season. The reigning World Champion, Masetti, could only manage third place while his new teammate Milani took second in the Championship.

1952 saw only minor modifications to the Gilera with the addition of a nose fairing and a redesign of the fuel tank for better ergonomics. Unfortunately, Geoff Duke put himself out of contention after an accident in a non-championship event at Schotten in Germany. Massetti went on to win the 500cc World Championship, the second title for himself and Gilera, with wins at the Dutch T.T. and Belgian G.P.

Team manager Taruffi broke with tradition for the 1953 season by signing Irishman Reg Armstrong and Englishman Dickie Dale alongside Masetti, Malani and Guiseppe Colnago as part of their rider line-up. But the bombshell came later when it was announced that the 1951 double World Champion Geoff Duke would be riding for Gilera as well after a falling out with the Norton management.

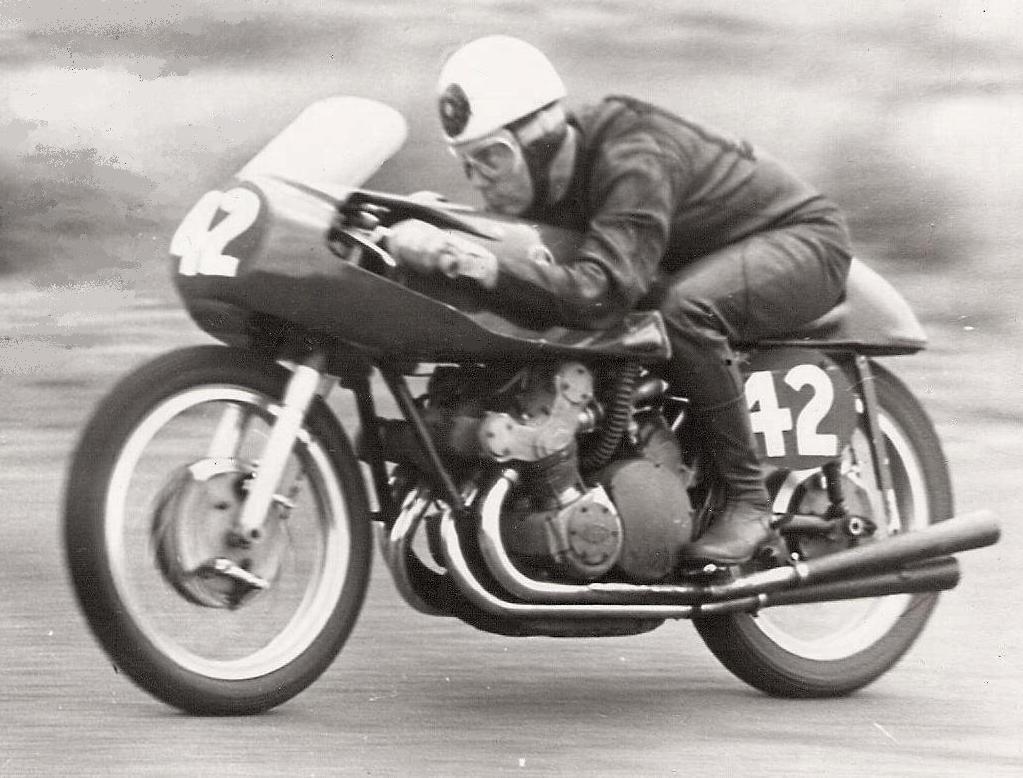

Ing. Pasoni carried out a number of modifications to the Gilera after extensive testing at Monza by the foreign riders, led by Geoff Duke. This brought about what many called the Nortonised Gilera, although the engine remained almost unchanged. The season opener was the Isle of Man T.T., and with the likes of Duke and Armstrong in its rider line-up, Gilera contested the event for the first time. Unfortunately, while dueling with Ray Amm, Duke crashed out on soft bitumen when accelerating away from Quarter Bridge. The best Gilera could manage was a third-place for Armstrong. But for the rest of the classics, Gilera dominated, with Duke clinching the World Championship.

Development of the Gilera didn’t stop, and Ing. Passoni instigated a major redesign of the cycle parts and engine for the 1954 season. Duke again dominated, winning five rounds in a row, Belgium, Holland, Germany, Switzerland and The Nations G.P. at Monza, out of the nine-round series. However, the Ulster round was not counted as it did not meet the FIM minimum distance as officials shortened it due to bad weather.

Apart from adopting a large air scoop for the front brake and enclosed dolphin fairings for all the factory bikes, the 1955 500cc Gilera was unaltered. Gilera’s first World Champion, Massetti, had left the team to join the MV Agusta squad. The Gilera rider line-up now consisted of Duke, Armstrong, Liberati, Milani, and Colnago. Martin, Monneret, and Veer also rode for the team.

1955 was to be Duke’s final dominant season. Wins came at the French, the British, the West German, and the Dutch T.T. Geoff may have won more races, but the Gilera’s had suffered from a batch of improperly heat-treated valve springs. Armstrong finished second in the Championship and Colgano fourth. Gilera also wrapped up its fourth 500cc Constructors World Championship. But it was the privateer rider’s strike at the Dutch round that would undermine Gilera’s 1956 season. Duke and Armstrong supported the strike and were banned from the Grand Prix for the first half of 1956, while Colnago and Milani were suspended for four months. Piero Taruffi also quit the team as manager, and Giuseppe’s enthusiastic son Ferrucio Gilera took over.

Ing. Passoni, however, had made more improvements for 1956 during the offseason. A new dustbin fairing with superior aerodynamics to that of the previous design. The frame was also beefed up, and the exhaust system now boasted four megaphones upping the power output to 70bhp at 11,000rpm, although the racer’s weight had increased to 150kg (330lb).

Due to the FIM ban on its riders, Gilera missed the Isle of Man T.T. and its Dutch equivalent. MV Agusta had signed another English rider named John Surtees, who romped home in first place at both T.T.’s. Duke built up a one-minute lead at Spa in Belgium on his return to the classics and set the fastest lap. Unfortunately, poor fuel quality destroyed a piston, and Duke retired two laps from the finish. Surtees won, his third of the six-round series, and had an almost unassailable lead in the Championship.

Some hope appeared for Duke when Surtees broke his arm during the 350cc race in Germany at the Solitude track. His Gilera teammates salvaged some pride with Armstrong winning the race with Pierre Monneret third. Again, misfortune came Duke’s way, and magneto trouble spelt the end of any Championship aspirations.

Duke came off at the next round, the Ulster G.P., and Armstrong suffered gearbox failure. This left the final round, The Nations G.P. at Monza. Gilera had given Liberati a more powerful and better handling machine in the hope of a popular Italian home victory. Much to the crowd’s dismay, Duke caught and passed his teammate. After a fierce battle, Geoff held on to win his first race of the season. Both Gilera riders had recorded the same time to claim the fastest lap.

In October that year, Giuseppe Gilera’s only son died tragically of a heart attack while visiting a subsidiary in Argentina. Giuseppe lost not only his son but also his passion for Grand Prix racing. From this point on, the company went into an irreparable gradual decline.

The previous month Reg Amstrong had won at the Avus circuit in Berlin, Germany, and announced to Gilera that he was retiring. As a result, Bob McIntyre was drafted into the team on Duke’s recommendation for the 1957 season. But misfortune followed Duke into the season opener at Imola, where he crashed spectacularly and put himself out for most of the classics. Liberati won the opening 500cc Grand Prix at Hockenheim in Germany from McIntyre, who suffered electrical issues. Liberati “took the double” by winning the 350cc class riding the new sleeved down version of the 500cc machine.

McIntyre struck back at the Isle of Man, winning the 500cc and 350cc Golden Jubilee T.T.’s. A new version of the 500cc racer had arrived midweek and featured a lighter frame with a removable bottom frame rail copied from the 350cc version and a neater “dustbin” fairing complete with built-in pannier fuel tanks. The end result was the first over 100mph (160.934kph) lap of the Island course. Aussie Bob Brown had been drafted into the team and repaid the opportunity with two fine third places.

At the Dutch T.T., McIntyre fell after stopping to change a faulty spark plug while pursuing the reigning World Champion, Surtees, on the MV Augusta. The result was an ongoing neck injury that would plague McIntyre for the remainder of the season. Liberati claimed second place to Surtees, adding to his points tally. At Spa in Belgium, the new team manager for the season, Roberto Persi, appropriated Brown’s Gilera when Liberati’s machine refused to fire. Liberati went on to win the race, although he was later disqualified after protests by MV Agusta and Norton. The race win was handed to Jack Brett on a Norton. A counter-protest by Gilera finally had the race awarded to Liberati in January 1958.

Duke returned for the final two rounds of the Grand Prix season at the Ulster and Italian Grand Prix. Liberati surprised many by winning the penultimate Ulster Grand Prix after Surtees, who was riding away, had machine failure. MacIntyre and Duke took second and third, respectively. In Italy, McIntyre had outclassed Liberati by winning the 350cc category but could not make the grid for the 500cc event ending up in Hospital with a bilious attack. Liberati sealed the 500cc Championship at Monza with a win while Duke finished in second with Milani in third.

Monza brought down the curtain on the 1957 Grand Prix season, with Liberati 500cc World Champion and Gilera achieving a fifth manufacturers title. Unexpectedly, Gilera, Moto Guzzi and Mondial all pulled out of racing. The tragic loss of Guiseppe’s son and the increasing cost of racing made the decision easy for Gilera to make. But sadly, it also heralded the end of a golden era in road racing.

Words Geoff Dawes © 2022. Images courtesy of thevintagent.com, bowiki.info and pinterest.it.